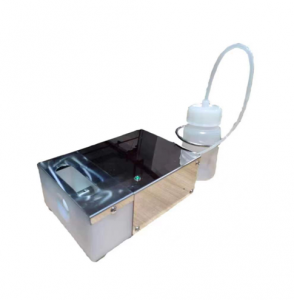

Plastic Loader Machine: Top Solutions for Your Business

A plastic loader machine, also known as a material loader or resin loader, is an automated equipment used in the plastic molding industry to transport and load plastic pellets or granules into an injection molding machine or extruder.The main purpose of a plastic loader machine is to streamline the material handling process and ensure a consistent and efficient supply of plastic material to the molding or extrusion equipment. Here's how it generally works:Material Storage: Plastic pellets or granules are usually stored in large containers or hoppers. These containers can be either mounted on the loader machine itself or located nearby, connected to the machine through material conveying systems like pipes or hoses.Conveying System: The loader machine is equipped with a motorized conveying system, typically an auger, that transports the plastic material from the storage container to the processing equipment. The conveying system may also incorporate other components like vacuum pumps, blowers, or compressed air to assist in material transfer.Control System: The loader machine is controlled by a central control system that allows the operator to set and adjust various parameters such as material flow rate, conveying speed, and loading sequences. This control system ensures accurate and consistent material loading.Loading Process: When the plastic molding or extrusion machine requires more material, the loader machine is activated. The control system initiates the conveying system, which then transfers the plastic material from the storage container to the processing equipment.Monitoring and Safety Features: Some loader machines are equipped with sensors and monitoring devices to ensure proper material flow and prevent issues like material shortages or blockages. Safety features such as alarms or emergency stop buttons may also be included to maintain operator safety.By using a plastic loader machine, manufacturers can automate the material loading process, reducing manual labor and improving efficiency. This ensures a continuous supply of material to the processing equipment, minimizing downtime, and optimizing production output.