Vaginal Speculum Mold for Medical Use

Our vaginal speculum molds are precision engineered for medical applications, ensuring the production of high-quality medical devices. With a focus on accuracy and reliability, the mold is designed to meet strict medical standards and provide the necessary precision for the manufacture of vaginal speculum used in medical examinations.

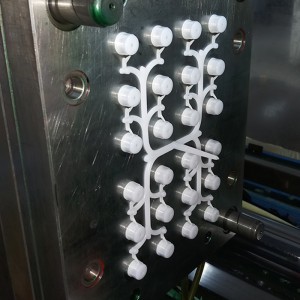

A vaginal speculum mold is a specific type of mold used in the manufacturing process of vaginal speculums. Vaginal speculums are medical instruments used during gynecological examinations to open and hold open the walls of the vagina. The mold is used to produce the speculum by injecting a suitable material into the mold cavity and then allowing it to solidify and take the shape of the speculum.Here are three key aspects of how a vaginal speculum mold works:Mold Design: The mold for a vaginal speculum is typically designed to have two halves that come together to form the cavity where the speculum will be formed. The mold design includes features such as the shape and size of the speculum, the mechanism for adjusting the opening angle, and any additional features like light sources for enhanced visibility. It is important to have a precise and well-designed mold to ensure the speculum is produced with the desired shape and functionality.Material Injection: Once the mold is set up, a suitable material, often a medical-grade plastic such as polycarbonate, is injected into the mold cavity. The material is injected at high pressure using specialized machinery. The injection ensures that the molten material fills the mold cavity completely, taking the shape of the vaginal speculum. The tooling and equipment used for this process may vary depending on the specific requirements and scale of production.Cooling, Solidification, and Ejection: After the material is injected, it is left to cool and solidify within the mold. Cooling can be achieved through various methods, such as cooling plates or circulating coolants. Once the material has solidified, the mold is opened, and the finished vaginal speculum is ejected. The ejection can be facilitated by mechanisms like ejector pins or air pressure. Proper care is taken during ejection to ensure the molded speculum is not damaged.Overall, a vaginal speculum mold is an essential tool in the production of vaginal speculums. It enables the efficient and consistent manufacturing of speculums with the desired shape, functionality, and quality. Strict quality control measures are often implemented during the production process to ensure the final products meet the required specifications and comply with medical standards.

| 1.R&D | We receive customer 3D drawing or sample with details requirements |

| 2.Negotiation | Confirm with clients details about: the cavity, runner, quality, price, material, delivery time, payment item, etc. |

| 3.Place an order | According your clients design or chooses our suggestion design. |

| 4. Mould | First We send mould design to customer approval before We make the mould and then start production. |

| 5. Sample | If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory. |

| 6. Delivery time | 35~45days |

| Machine Name | Quantity ( pcs ) | The original country |

| CNC | 5 | Japan/Taiwan |

| EDM | 6 | Japan/China |

| EDM ( Mirror) | 2 | Japan |

| Wire Cutting ( fast ) | 8 | China |

| Wire Cutting ( Middle ) | 1 | China |

| Wire Cutting ( slow ) | 3 | Japan |

| Grinding | 5 | China |

| Drilling | 10 | China |

| Lather | 3 | China |

| Milling | 2 | China |