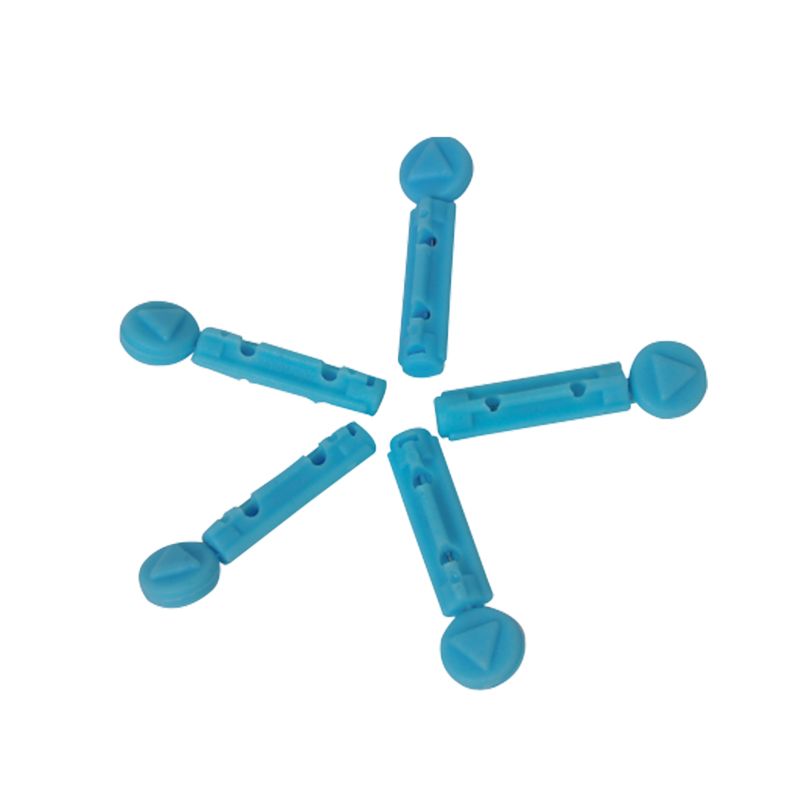

A lancet needle mold is a tool used in the manufacturing process to produce lancet needles, which are small, sharp needles typically used for diagnostic purposes such as blood glucose testing or blood sampling for various medical tests.The lancet needle mold is designed to create the desired shape and size of the lancet needle. It consists of two halves, usually made of steel, that come together to form a cavity where the molten material is injected.The mold is precision-engineered with intricate details and channels to ensure the proper formation of the lancet needle. These details include the needle tip shape, bevel design, and needle gauge.The manufacturing process typically involves injecting a molten material, such as stainless steel or medical-grade plastic, into the mold cavity. Once cooled and solidified, the mold is opened, and the finished lancet needles are removed.Quality control measures are implemented throughout the production process to ensure that the lancet needles meet the required specifications and standards for safety and functionality. This includes inspecting the mold for any defects or irregularities that may affect the quality of the needles produced.Overall, the lancet needle mold plays a crucial role in producing high-quality and precise lancet needles, which are essential tools in many medical procedures.